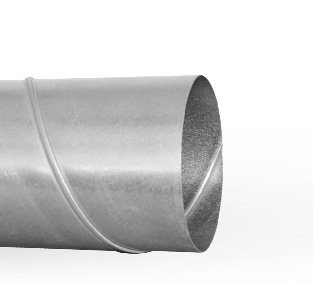

Spiral ductwork refers to a type of air duct commonly used in HVAC (heating, ventilation, and air conditioning) systems. Here’s a detailed overview:

What is Spiral Ductwork?

Spiral ductwork is a cylindrical duct made from sheet metal formed into a continuous spiral seam. Unlike rectangular ducts, spiral ducts are round and can come in 3mtr lengths as standard with a variety of diameters ranging from 80Ø to 1600Ø. The spiral design adds structural strength, which can allow for longer duct runs with fewer supports.

Materials

Spiral ductwork is primarily made from the following materials:

1. Galvanized Steel: The most common material due to its durability and resistance to corrosion. DX51 Z140

2. Aluminum: Lightweight and resistant to corrosion, often used in environments where moisture is a concern.

3. Stainless Steel: Highly durable and resistant to corrosion and high temperatures, used in specialized applications like food processing or chemical plants.

Uses

Spiral ductwork is used in a variety of applications, including:

- Commercial Buildings: For HVAC systems in offices, retail stores, and other commercial properties, providing efficient airflow distribution, commercial kitchen ventilation systems

- Industrial Facilities: In factories and plants where robust and durable ducting is required to handle large volumes of air and potentially harsh conditions.

- Residential Buildings: Less common but sometimes used in homes for specific heating and cooling requirements

- Ventilation Systems: For general building ventilation, including exhaust and fresh air intake systems

- Exposed Ductwork: The aesthetic appeal of spiral ducts makes them popular in modern architectural designs where ducts are left exposed, such as restaurants or industrial-style buildings

Advantages

- Strength: The spiral seam adds structural integrity, allowing for longer spans without additional support.

- Efficiency: Round ducts have less surface area compared to rectangular ducts, reducing air resistance and improving airflow efficiency.

- Leakage: The continuous seam design reduces the likelihood of air leaks compared to traditional rectangular ducts.

- Aesthetics: The uniform, sleek appearance is visually appealing in exposed installations.

Installation

Installation of spiral ductwork involves cutting the ducts to the required lengths, connecting sections with male couplings or fittings, and securing the ducts in place using rivets or self tapping tek screws. The ductwork is then supported by an array of methods depedning on what it is being supported from. Proper sealing and insulation is also be necessary to ensure energy efficiency and prevent air leaks

In summary, spiral ductwork is a versatile and efficient option for various HVAC and ventilation applications, valued for its strength, efficiency, and aesthetic appeal